Use Purpose-Built Chargers to Get the Most from Lithium Iron Phosphate Batteries

In lithium iron phosphate (LiFePO4) batteries, LiFePO4 is used for the cathode of the battery, with a metallic-backed graphite carbon material acting as the electrode. First described by University of Texas researchers in 1996, they are not a new technology. However, electrochemistry is garnering a lot of interest because it offers some advantages over lithium-ion (Li-ion) cells. These advantages include lower cost, non-toxicity, the widespread availability of iron, and excellent thermal stability. In contrast, the nickel and cobalt used in Li-ion batteries are hard to source, expensive, and more environmentally damaging.

Moreover, LiFePO4 can go through many more charging cycles than equivalent Li-ion cells. Depending on how the battery is used, from 1,000 up to 10,000 cycles are possible. Also, a standard qualified LiFePO4 battery can offer at least 80 percent discharge capacity (or “depth of discharge”) for at least 2000 cycles. The equivalent characteristic of a typical Li-ion battery is 300 to 500 cycles.

Other features of LiFePO4 batteries include fast charging tolerance, a low internal resistance that allows them to support a high discharge current, and the supply voltage is remarkably stable. They also work well at high temperatures.

An example of a LiFePO4 battery is the PSL-FP-IFP2770180EC, a 3.2 volt, 25 ampere-hour (Ah) battery from Power Sonic Corporation (Figure 1).

Figure 1: A LiFePO4 battery is less expensive and offers more charging cycles than a Li-ion equivalent. (Image source: Power Sonic Corporation)

Figure 1: A LiFePO4 battery is less expensive and offers more charging cycles than a Li-ion equivalent. (Image source: Power Sonic Corporation)

However, there are some drawbacks that, until recently, have prevented LiFePO4 batteries from going mainstream. Key among these is a 15 to 25 percent lower energy density than Li-ion and a lower output voltage of 3.2 volts, compared to 3.7 volts for Li-ion. In addition, LiFePO4 batteries don’t work well at low temperatures, and generally require more care and protection than their more robust Li-ion cell counterparts.

Improvements in LiFePO4 energy density

Recent improvements in energy density have made LiFePO4 batteries more applicable across a wider range of devices. While they’re unlikely to replace Li-ion batteries in products such as cellphones or portable computers, in applications with more space and/or where low cost and easier recyclability are important, you may find them to be a good option. Examples include electric bikes (e-bikes) and some models of electric vehicles (EVs). For example, Tesla announced back in late 2021 that it would move to LiFePO4 batteries for its entry-level vehicles. The company’s batteries offer around 260 watt-hours per kilogram (Wh/kg), which is on par with the best Li-ion cells.

Figure 2: The Tesla Model 3 now takes advantage of LiFePO4 batteries. (Image source: Tesla)

Figure 2: The Tesla Model 3 now takes advantage of LiFePO4 batteries. (Image source: Tesla)

Designers are increasingly considering LiFePO4 batteries in applications where their low cost, long life, and benign electrical characteristics are more important than high energy density. Examples include radio-controlled devices, portable motor-driven products, and, notably, Industrial Internet of Things (IIoT) sensors.

As only a select group of engineers are involved in the design of exotic products such as EVs, it is in these more modest applications that you’re increasingly likely to find LiFePO4 power sources.

Handle with care

Li-ion and LiFePO4 share some similarities. For example, the energy comes from the movement of lithium ions, which frees up electrons to create an electric current to power a device. However, one important difference is in how the batteries are charged. LiFePO4 batteries have different electrical characteristics to Li-ion, altering the charging profile. The variation is subtle but important to understand in order to realize the maximum potential of LiFePO4.

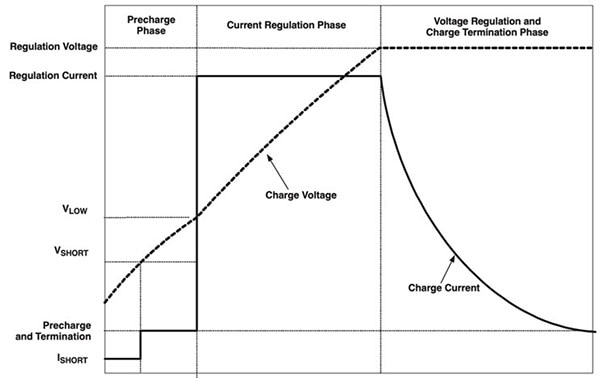

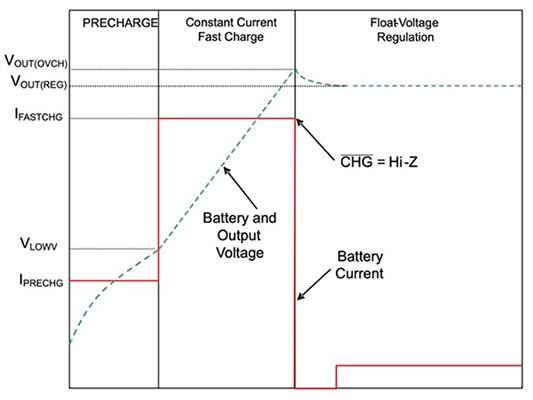

Figures 3 and 4, courtesy of Texas Instruments, show the difference between a typical Li-ion and LiFePO4 charging profile. The LiFePO4 charging algorithm (Figure 4) doesn’t require the constant voltage (CV) mode typical of the Li-ion battery charge cycle (Figure 3). Instead, the battery is rapidly charged with a fast-charge constant current (CC) to an overcharge voltage and then allowed to “relax” to a lower float charge voltage threshold. The removal of the CV control reduces charge time significantly. During the charge cycle, an internal control loop typically monitors the power management IC (PMIC) junction temperature and reduces the charge current if its temperature threshold is exceeded.

Figure 3: Li-ion battery charging follows three distinct phases. First, the battery is charged with a modest constant current to precharge, followed by a higher constant charge to add energy quickly. Finally, when the charge voltage matches the battery output, the profile switches to a constant voltage to gently fill the battery to capacity. (Image source: Texas Instruments)

Figure 3: Li-ion battery charging follows three distinct phases. First, the battery is charged with a modest constant current to precharge, followed by a higher constant charge to add energy quickly. Finally, when the charge voltage matches the battery output, the profile switches to a constant voltage to gently fill the battery to capacity. (Image source: Texas Instruments)

Figure 4: LiFePO4 battery charging is different than Li-ion. After precharge, the battery is charged to full capacity using a constant current. The voltage is then allowed to first “relax” and then float by using a small top-off charge. Compared to the Li-ion cycle, the charging of LiFePO4 batteries is faster. (Image source: Texas Instruments)

Figure 4: LiFePO4 battery charging is different than Li-ion. After precharge, the battery is charged to full capacity using a constant current. The voltage is then allowed to first “relax” and then float by using a small top-off charge. Compared to the Li-ion cycle, the charging of LiFePO4 batteries is faster. (Image source: Texas Instruments)

A further difference between the charging profiles is the lower maximum charging voltage for the LiFePO4 battery due to the difference in the battery chemistries. The maximum charging voltage for the LiFePO4 battery is capped at an overvoltage of 3.6 volts before dropping back to 3.5 volts, whereas for the Li-ion battery, it is limited to 4.1 or 4.2 volts.

Compact chargers for LiFePO4

The increased use of LiFePO4 has encouraged chip companies to introduce monolithic ICs dedicated to charging the cells using an optimized profile. These allow for incorporating the technology without having to design a power management circuit from scratch.

One example is the BQ25070DQCR LiFePO4 PMIC from Texas Instruments. The device comes in a 2 x 3 millimeter (mm) package, supplies a 3.7 volt overcharge voltage, and a 3.5 volt float voltage at up to 1.2 A.

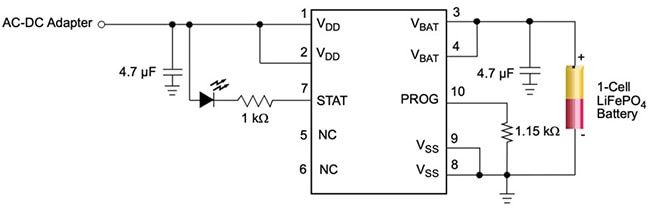

A second example is the MCP73123T-22SI/MF from Microchip Technology. The device operates from a 4 to 16 volt input and offers a maximum charge current of 1.1 A. The fast-charge CC value is set with an external resistor from 130 milliamps (mA) to the upper limit, depending upon the battery being charged. The MCP73123/223 also limits the charge current based on die temperature during high power or high ambient temperature conditions (Figure 5).

Figure 5: Microchip Technology’s LiFePO4 PMIC schematic. The resistor connected to the PROG pin sets the maximum charge current. (Image source: Microchip Technology)

Figure 5: Microchip Technology’s LiFePO4 PMIC schematic. The resistor connected to the PROG pin sets the maximum charge current. (Image source: Microchip Technology)

A third solution comes from Analog Devices. The MAX77787JEWX+ PMIC operates from an input voltage of 4.5 to 13.4 volts and has a maximum charge current of 3.15 A. The fast-charge current and termination voltage are configured with external resistors. The 2.75 x 2.75 mm device supports both LiFePO4 and Li-ion charging.

Conclusion

Despite having trade-offs relative to Li-ion in energy density and supply voltage, LiFePO4 batteries offer more charging cycles and rapid charging advantages. Additionally, they suit many cost-sensitive applications including EVs and IIoT sensors. Purpose-designed monolithic chargers make it easy to use the battery chemistry, safe in the knowledge that optimized charging profiles will ensure long life and reliability.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum